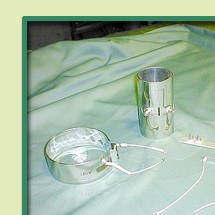

| Mica

heater plate: |

|

|

|

The JAW belt heater is most suitable to be fixed on the external of feeding cylinder of the plastic injector serving as cylindrical heater for conductive heating. This heater used quality mica as base material, the mica has small thermal absorption characteristic and quick response to temperature, with the feature of shortening the temperature rise time. The basic structure is winding the quality nickel chromium wire evenly on the mica sheet, and then sandwich with mica on top and bottom for insulation and laminated by steel plate or stainless steel externally and then bend in cylindrical formation. The single sheet type with one division on the heater, and double sheet type with two division, the standard type employs tying structure by tie, the power terminal is screw stud as standard and may by supplied as lead type under request, but the mechanical strength is not durable due to this structure. The JAW belt type heater possess smooth surface and elasticity, but correct size should be selected in order to ensure the high thermal conductivity of the heating substance. When mounted on the feeding cylinder, the ID of the heater should contact closely, if failed to do so and there is gap existed, the surface will exceed the allowable temperature due to poor thermal conductivity, this overheated portion will extend continuously and affect the service life. |

|

|

|

|

|

|

|

|

| |

|

|

|